In steel structure buildings, Steel Truss is a key load-bearing component, and its durability and maintenance cost directly affect the safety and economy of the overall building. Since steel is susceptible to oxidation corrosion in the natural environment, it is essential to effectively treat it with anti-rust. At present, spraying and galvanizing are two common methods for anti-rust treatment of Steel Truss.

Advantages and considerations of spraying treatment

Advantages:

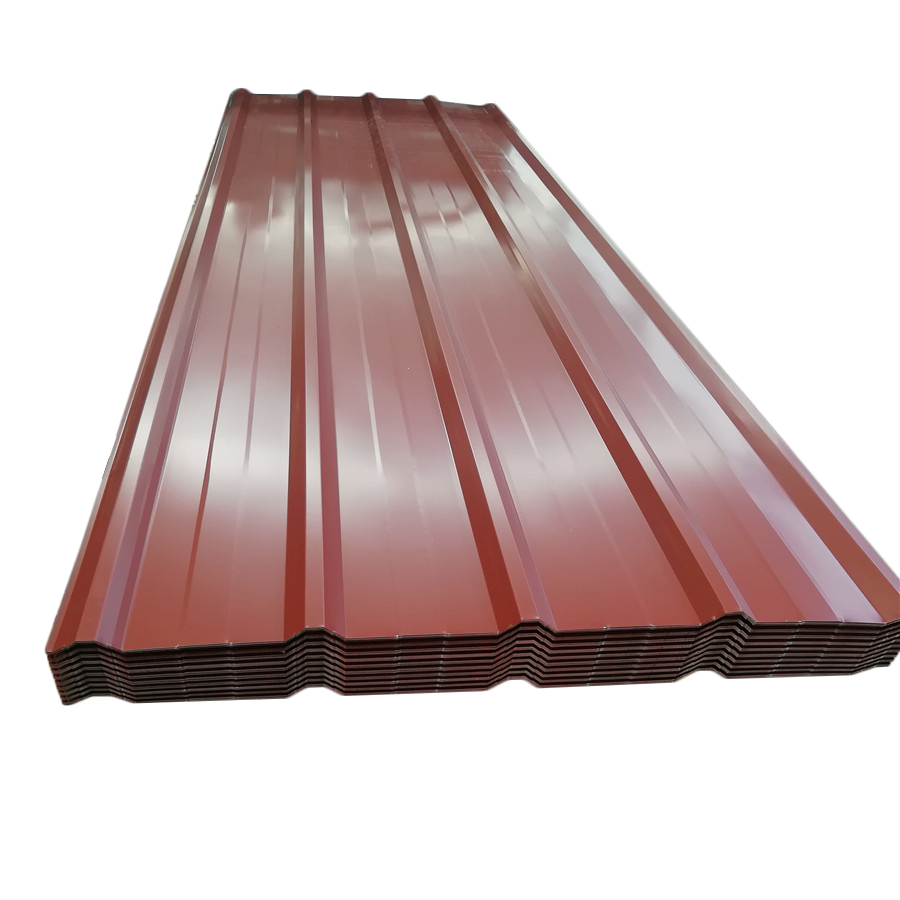

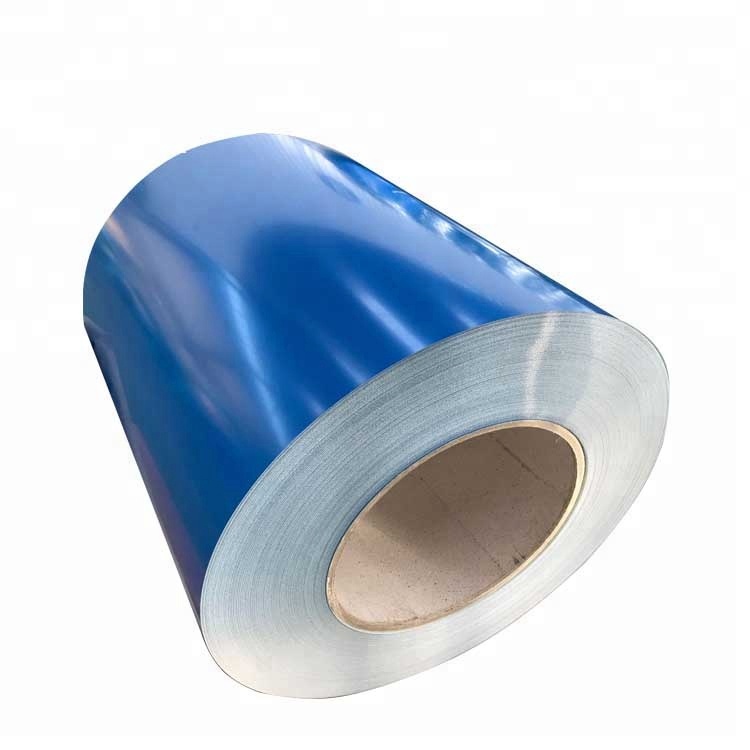

Diversity and aesthetics: Spraying can provide a rich selection of colors and texture effects, which can not only protect steel from corrosion, but also enhance the visual effect of the building's appearance and meet diverse design needs.

Wide adaptability: Spraying is suitable for almost all types of steel surfaces, including complex shapes and hard-to-reach corners, ensuring full coverage and effectively isolating air and moisture.

Easy to repair: If the coating is damaged, it can be partially repaired by re-spraying, which is relatively low in cost and easy to operate.

Considerations:

Maintenance cycle: Spray coatings need to be regularly inspected and repainted to maintain their anti-corrosion properties, especially in harsh environmental conditions, where the maintenance cycle may be shorter, increasing long-term maintenance costs.

Environmental adaptability: Some coatings may fail faster under extreme temperature or humidity conditions, so it is necessary to select high-quality coatings and ensure the correct construction technology.

Advantages and considerations of galvanizing treatment

Advantages:

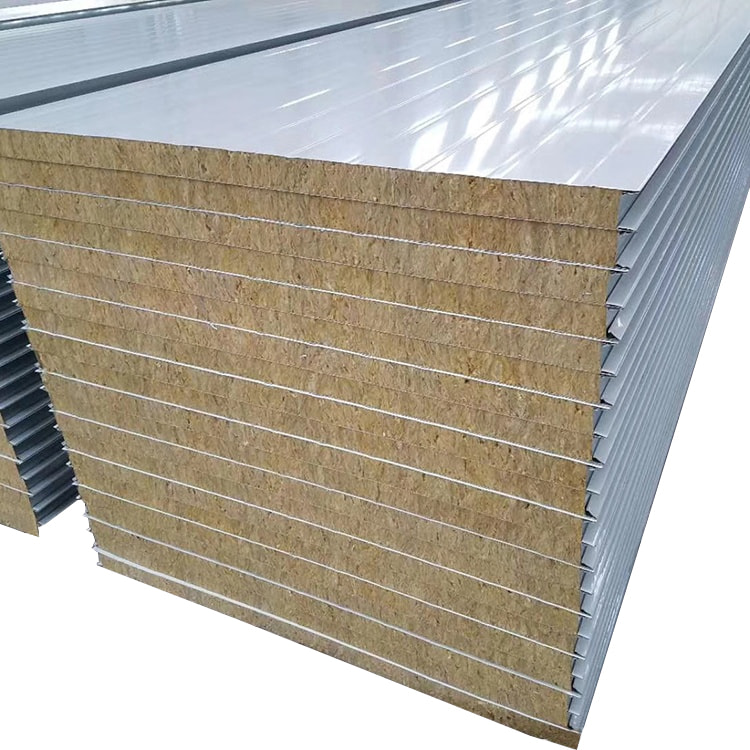

Long-term anti-corrosion: The galvanized layer forms a tightly bonded alloy layer with the surface of the steel, which has excellent corrosion resistance and can protect the steel from oxidation and corrosion for a long time.

Low maintenance cost: Once the galvanized layer is formed, almost no additional maintenance is required, which greatly reduces the maintenance cost in long-term use.

Environmentally friendly: The galvanizing process is relatively environmentally friendly, and when the galvanized steel is recycled and reused, the galvanized layer can be recycled together, which is in line with the concept of sustainable development.

Considerations:

Initial cost: The initial cost of galvanizing treatment may be higher than spraying because professional galvanizing equipment and processes are required.

Restrictions: For Steel Trusses of certain shapes or structures, galvanizing treatment may have certain limitations, such as difficult-to-handle internal or hidden parts.

Comprehensive analysis

From the perspective of long-term use, galvanizing is generally considered to be a superior choice due to its long-term anti-corrosion, low maintenance cost and environmental protection characteristics. Especially for Steel Truss that need to be exposed to harsh environments for a long time, such as seaside, industrial areas or high humidity areas, galvanizing can better play its advantages and ensure the safety and durability of the structure.

However, this does not mean that spraying is worthless. In certain circumstances, such as when fast construction is required, specific visual effects are pursued or budget is limited, spraying is still a viable option.