Steel Truss is widely used in projects such as bridges, industrial plants, stadiums and large exhibition halls due to its lightweight, high strength and high adaptability. Choosing the right type of steel truss for different project requirements has an important impact on the cost, stability and construction efficiency of the project.

In projects with large load requirements, the bearing capacity of the truss is a key factor. For long-span bridges or high-load industrial plants, space trusses are an ideal choice. This three-dimensional structure evenly distributes the load through a reasonable arrangement of rods and has excellent torsion resistance. The geometric design of the space truss can greatly reduce the amount of material used while improving the overall rigidity, making it suitable for complex load conditions.

If the project involves a large span but requires a low deadweight, such as an exhibition hall or a stadium, choosing a tube truss can achieve a good balance. The tube truss uses round tubes as rods, has high strength and bending resistance, and has a beautiful appearance, meeting the visual effect requirements of the building. This type of truss is often used in public buildings that need to take into account both functionality and aesthetics.

Lightweight trusses are an efficient choice for temporary or mobile structures that need to be installed quickly. This type of truss is mainly made of lightweight materials, which is easy to transport and assemble, and the construction period is significantly shortened. Lightweight trusses are widely used in temporary exhibition stands, outdoor event stages and mobile warehouses. Their flexibility and economy greatly improve engineering efficiency.

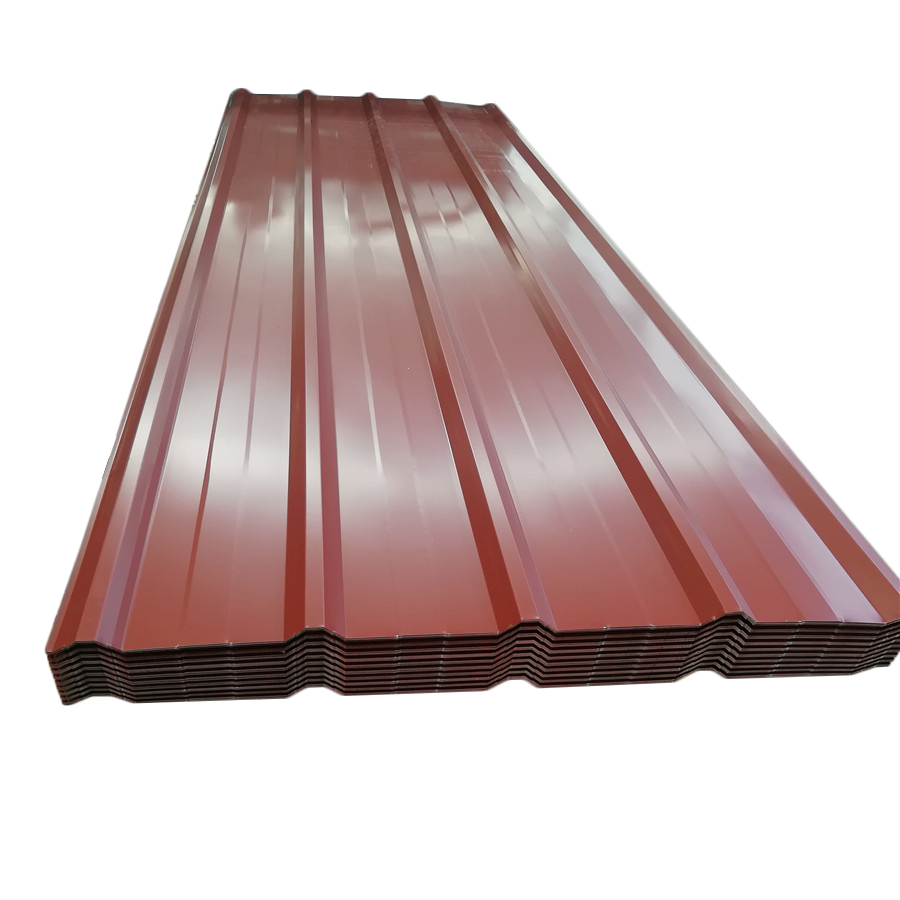

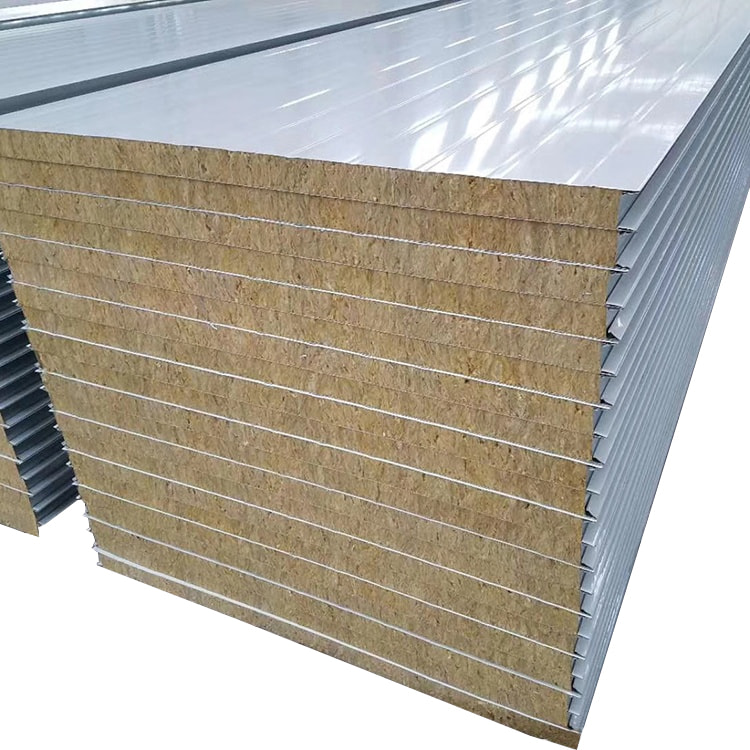

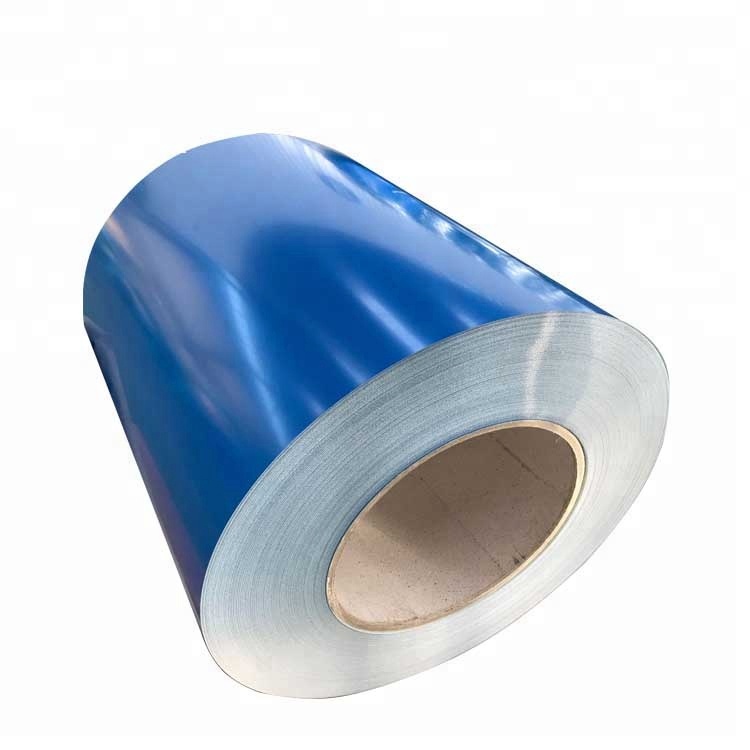

In highly corrosive environments or special-purpose scenarios, the choice of materials has a huge impact on the adaptability of steel truss types. For example, in chemical plants or coastal areas, stainless steel trusses or steel trusses with special anti-corrosion treatment can effectively cope with environmental corrosion. In special-purpose projects that require insulation or heat preservation, the composite design of steel trusses and insulation materials can be combined to achieve a balance between functionality and economy.

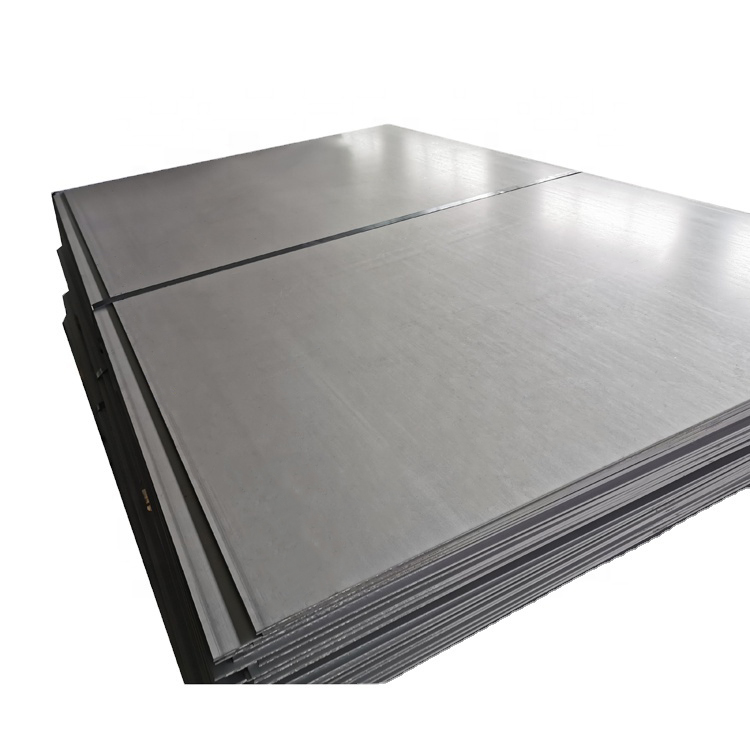

The construction environment is also an important consideration in choosing the type of steel truss. In areas with complex terrain or limited space, prefabricated trusses can be transported to the site after being produced in advance in the factory, reducing the difficulty of on-site construction. This method not only ensures the accuracy and quality of the trusses, but also reduces the construction period and cost.

The demand for economy cannot be ignored. In the case of limited budget, the use of standardized steel truss types can effectively control costs. Through optimized design and mass production, not only can material and manufacturing costs be reduced, but construction efficiency can also be improved to ensure that the project is delivered on schedule.