In the field of modern construction, Steel Truss is widely used due to its advantages such as high strength, good stability and fast construction speed. However, how to optimize Steel Truss design to save materials and costs to the maximum extent while ensuring structural safety has become a common goal pursued by many designers and engineers.

The key to optimizing Steel Truss design lies in accurate calculation and simulation. Through advanced structural analysis software, we can simulate the stress conditions of the truss in detail to find the optimal cross-sectional size and shape. For example, in areas with less stress, the cross-sectional size can be appropriately reduced, while at nodes with greater stress, a reinforced design is adopted. This precise calculation method can not only ensure structural safety, but also effectively reduce material consumption and reduce costs.

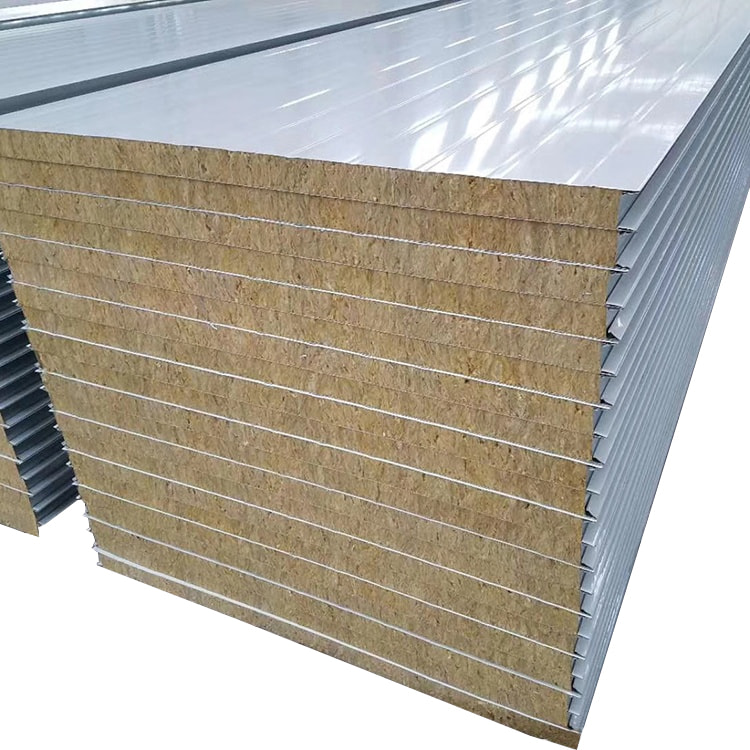

Adopting modular design concepts is also an effective way to save materials and costs. By designing standardized truss modules, mass production and rapid assembly can be achieved, which not only improves construction efficiency but also reduces production costs. At the same time, modular design is also convenient for maintenance and replacement, extending the service life of the structure.

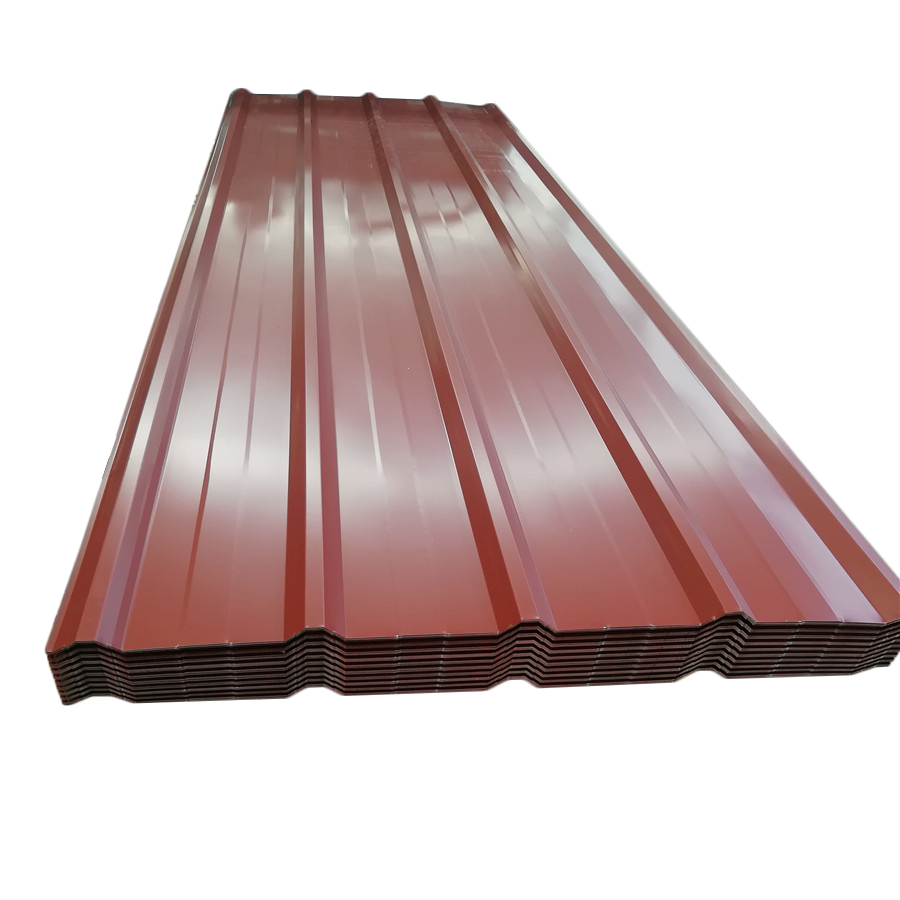

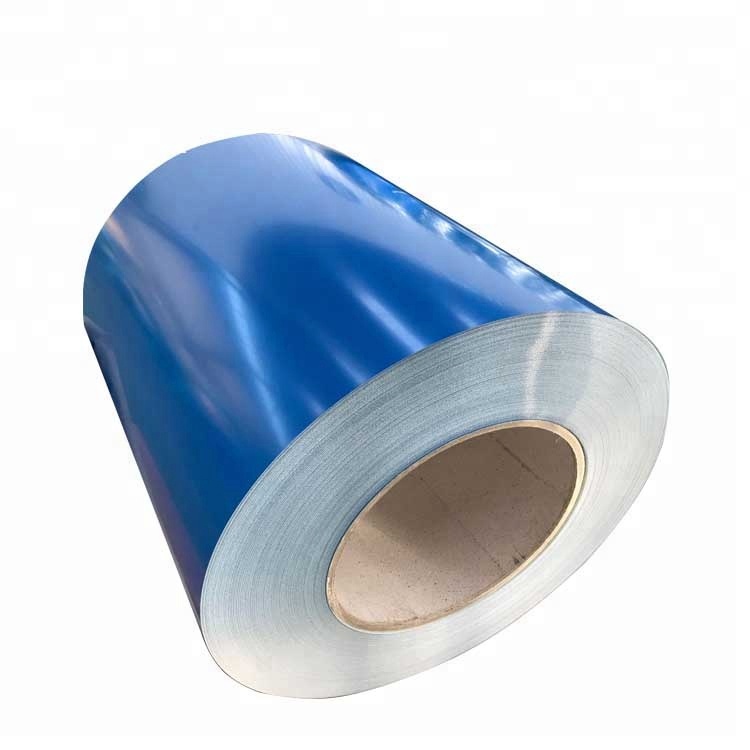

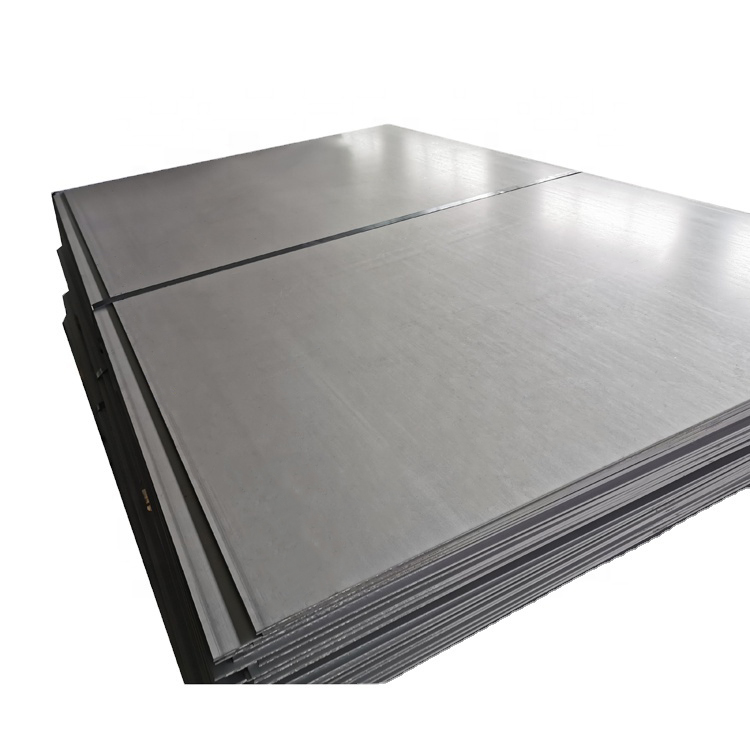

In terms of material selection, we can also seek optimization. By comparing the performance and price of different materials, choose the most cost-effective steel. For example, high-strength low-alloy steel not only has excellent mechanical properties, but also can reduce material consumption and reduce costs to a certain extent. In addition, considering the recyclability and environmental protection of materials is also an important part of modern design that cannot be ignored.

To optimize the design of Steel Truss, attention should also be paid to detail processing. For example, at the node connection, advanced welding and bolt connection technology is used to ensure structural stability while reducing material waste. In terms of anti-corrosion treatment, long-lasting anti-corrosion coatings or hot-dip galvanizing processes are used to extend the service life of the structure and reduce subsequent maintenance costs.

We are well aware that optimizing the design of Steel Truss is not only about saving materials and costs, but also about the safety and stability of the structure. Therefore, we always adhere to the principle of "safety first, quality-oriented", and provide customers with more economical, safe and efficient steel truss solutions through continuous technological innovation and design optimization.