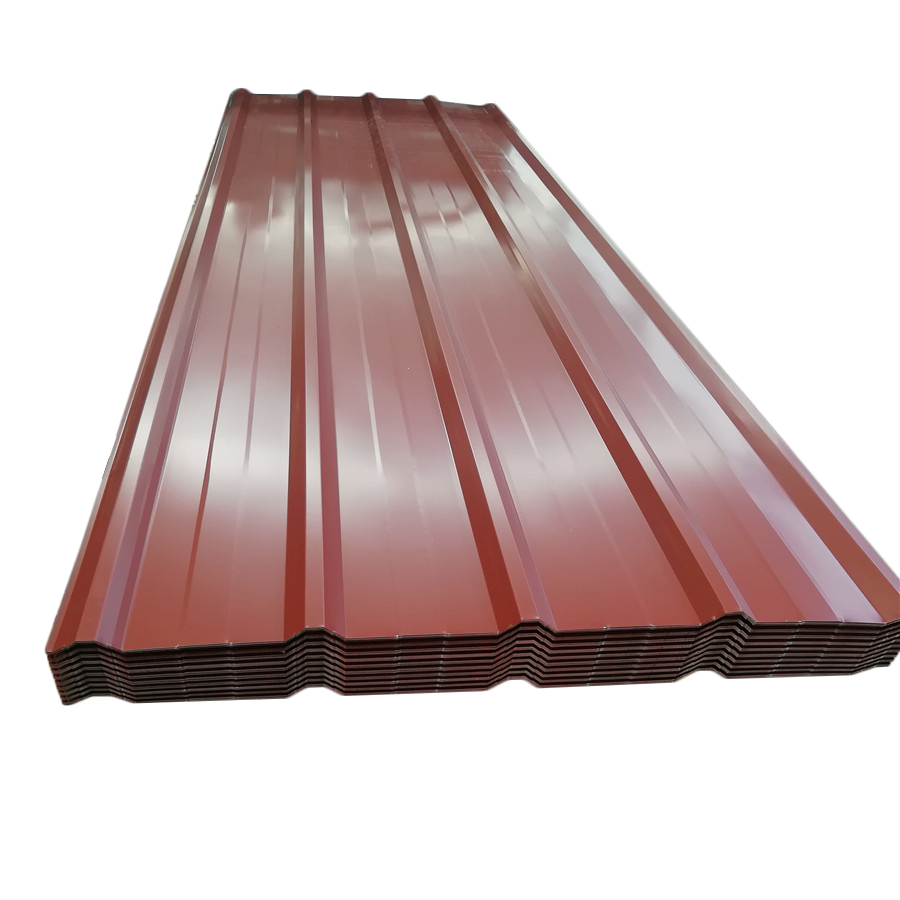

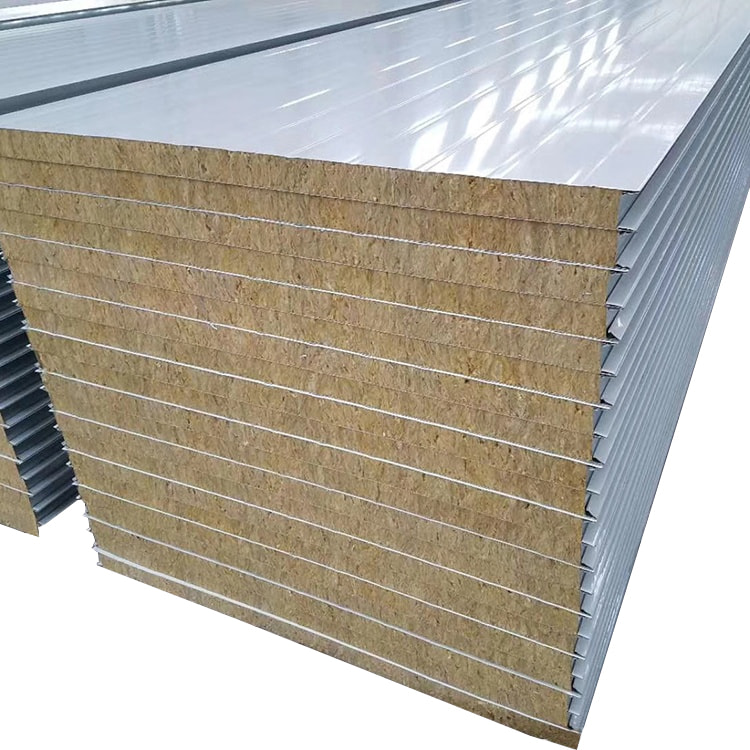

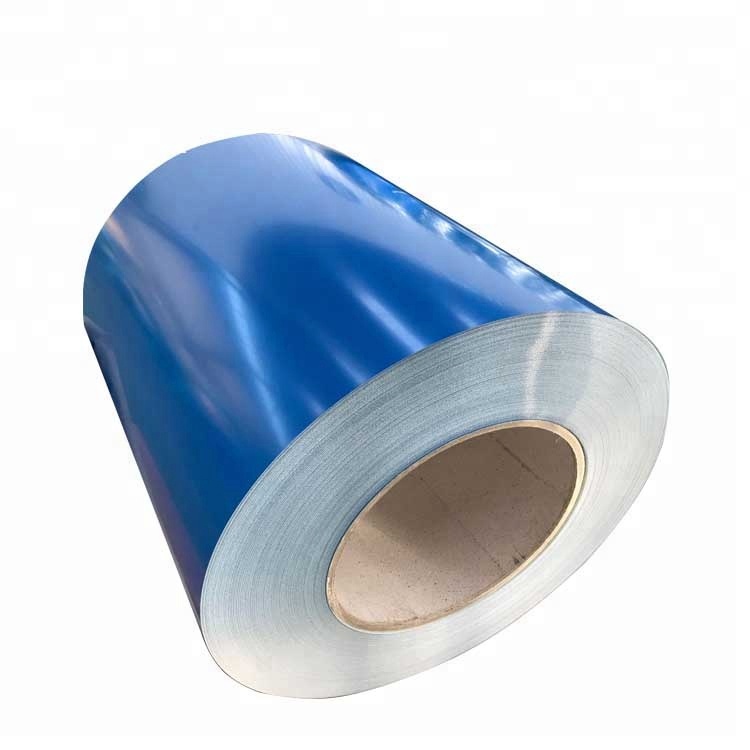

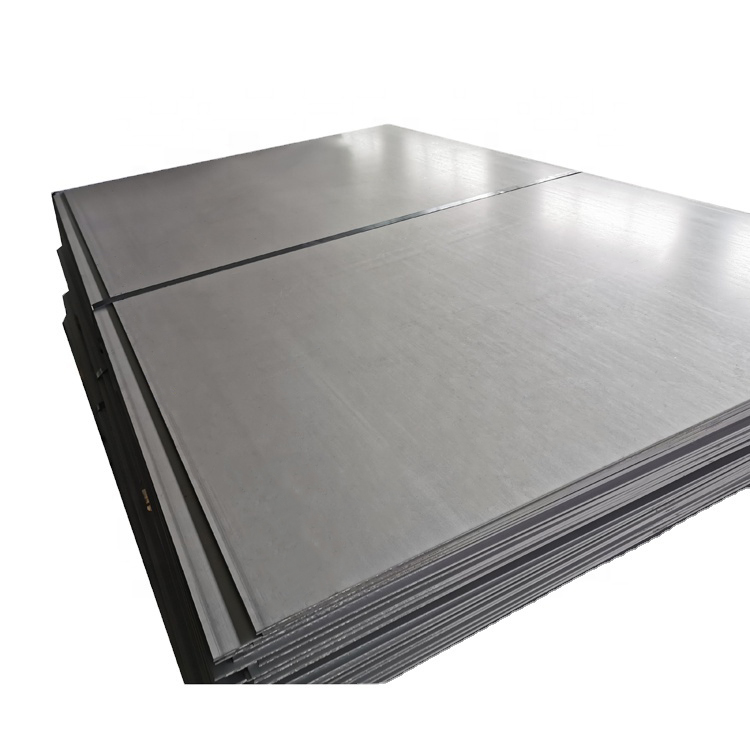

In the construction industry, steel purlins play a crucial role in providing structural support to roofs and walls. Determining the optimal spacing of steel purlins is essential to ensure the stability and integrity of the entire structure. The first step in determining the best spacing for steel purlins is to consider the load requirements. s. The type of roofing material also influences the purlin spacing. For example, heavier roofing materials such as clay tiles or concrete panels will require closer purlin spacing compared to lighter materials like metal sheets or asphalt shingles. This is because the heavier materials exert more downward force on the purlins, requiring more support. The span of the building is another important factor. Longer spans require stronger and more closely spaced purlins to prevent sagging and ensure structural stability. Shorter spans may allow for wider purlin spacing, but still need to be carefully calculated to ensure that the structure can withstand the expected loads. The design of the steel purlins themselves also affects the spacing. Different profiles and thicknesses of purlins have different load-bearing capacities. Thicker and more robust purlins can often be spaced farther apart, while thinner purlins may need to be closer together to provide sufficient support. In addition to load and design considerations, local building codes and regulations must be adhered to. These codes provide guidelines for purlin spacing based on such factors as climate, seismic activity, and building use. Failure to comply with these codes can result in structural failures and potential safety hazards. Once the optimal purlin spacing has been determined, it is essential to install the purlins correctly. This includes ensuring that they are properly aligned, securely fast corrected, and supported at the intervals. Any deviations from the recommended spacing or installation methods can compromise the structural stability of the building. In conclusion, determining the best spacing for steel purlins is a complex process that requires careful consideration of load requirements, roofing materials, building span, purlin design, and local building codes. By taking these factors into account and using accurate engineering calculations, builders can ensure that their structures are stable, safe, and able to withstand the forces of nature and everyday use.