Steel Purlin plays a vital role in modern building structure, and its key role is reflected in many aspects.

1. Load-bearing function

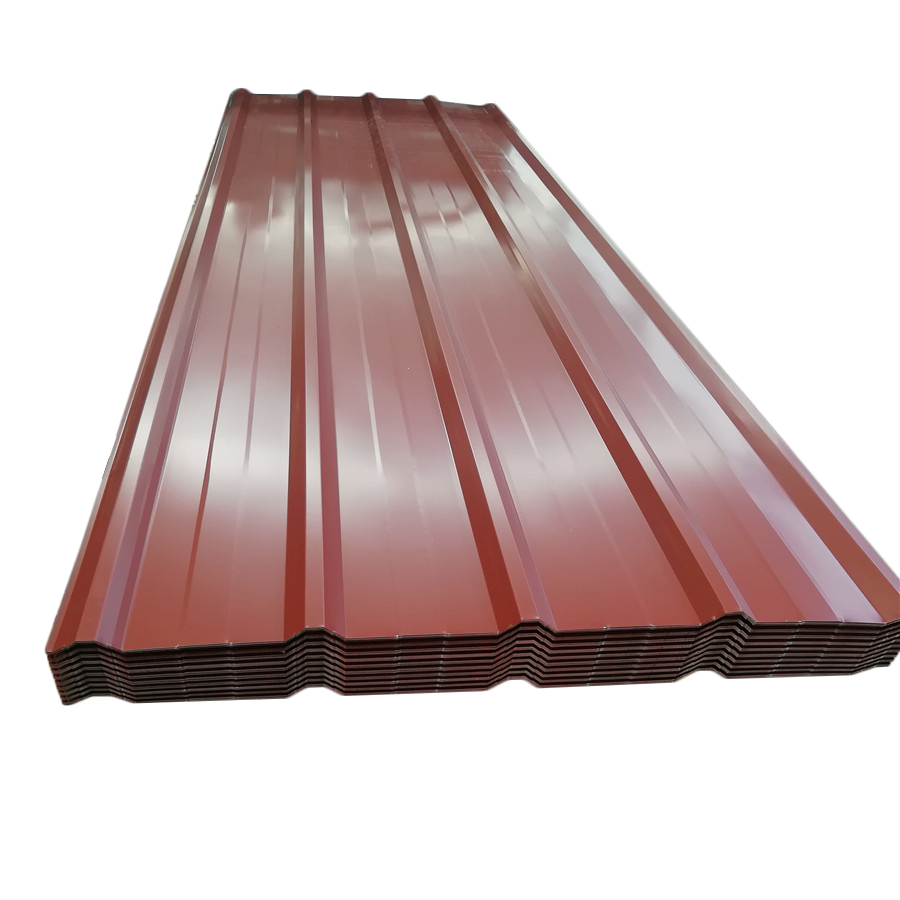

Steel purlin is mainly used to bear the load of roof and wall. In light steel structure buildings, the weight of roofing materials such as color steel plates and metal tiles needs to be transferred to the main structural frame through steel purlin. It can evenly distribute these loads to avoid excessive local pressure causing structural deformation or damage. For example, in industrial plants, the roof may also bear variable loads such as snow load and wind load. Steel purlins can effectively bear these additional loads and ensure the stability of the building roof with their high-strength steel characteristics.

2. Space separation and support

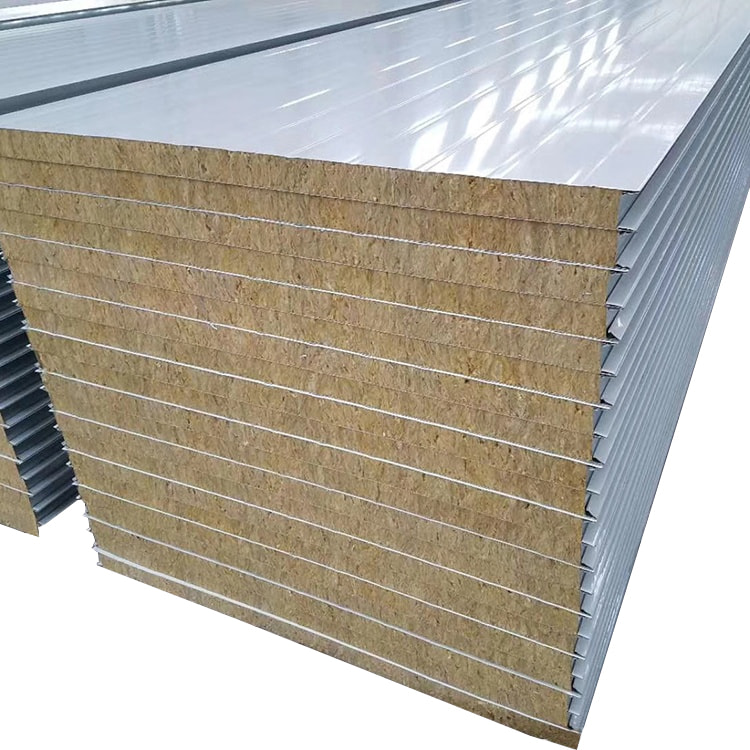

Steel purlin plays a certain role in separation and support in building space. It can serve as a supporting skeleton for the roof system and wall system, and determine the shape and structure of the roof and wall. In large-span buildings, the reasonable arrangement of steel purlins can reduce the span of the main structural beams and the force requirements of the main structure, thereby saving steel and reducing construction costs. At the same time, steel purlins can also provide installation support points for the ceiling, ventilation ducts, lighting equipment, etc. inside the building, which is convenient for the layout and installation of facilities inside the building.

3. Improve structural stability

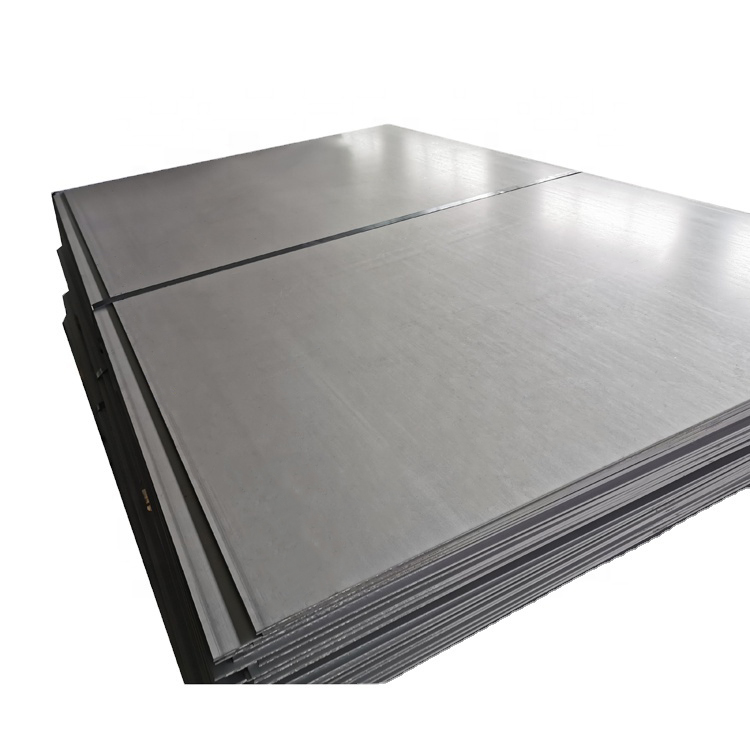

The steel purlins and the main structural frame form an integral structure through reliable connection methods (such as bolt connection, welding, etc.), which enhances the overall stability of the building. It can resist horizontal wind loads and horizontal forces generated by earthquakes. In earthquake-prone areas, reasonably designed and installed steel purlins can cooperate with the main structural frame for earthquake resistance and reduce the degree of damage to the building in an earthquake.

4. Convenient construction and installation

The prefabrication and standardized production of steel purlins make it have a high installation efficiency at the construction site. Construction personnel can quickly install the steel purlins to the predetermined position according to the design drawings, and the weight of the steel purlins is relatively light, which is convenient for lifting and installation operations. This not only shortens the construction period of the building, but also reduces the safety risks during the construction process.

5. Durability and maintenance

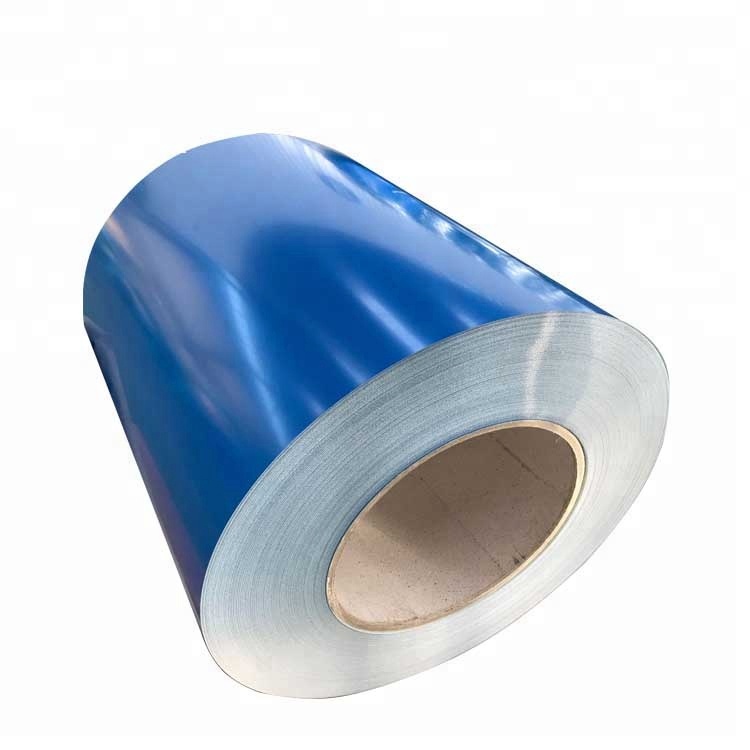

Steel itself has good durability. Steel purlins that have been treated with anti-corrosion (such as galvanizing, painting, etc.) can be used for a long time under different environmental conditions. Compared with some wooden purlins, steel purlins are not easy to decay or be eaten by insects, which reduces the maintenance cost and frequency of the building during use.