During the design stage, the effects of wind load and earthquake load should be fully considered. Through precise calculation and analysis, the reasonable structural form and size of the steel truss can be determined. For example, the use of stable structural forms such as triangles or trapezoids can effectively improve the overall stability of the steel truss. At the same time, according to the wind load and earthquake intensity level of the building area, the cross-sectional size and material strength of the steel truss should be reasonably determined to ensure that it will not be excessively deformed or damaged when bearing the design load.

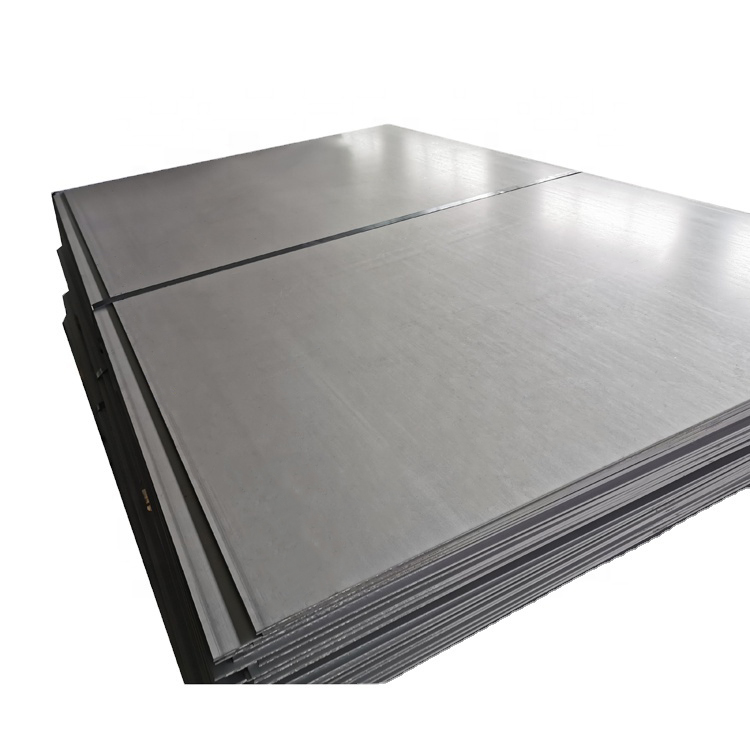

The selection of materials is also crucial. High-strength and high-toughness steel, such as Q345 steel or higher strength grade steel, should be selected. These steels have good mechanical properties and can maintain good bearing capacity and deformation capacity under external forces such as wind disasters and earthquakes. At the same time, it is necessary to ensure that the quality of the steel meets the relevant standards, and after strict inspection and testing, avoid using steel with quality defects.

Node connection is a key link that affects the wind and earthquake resistance of steel trusses. Use reliable connection methods, such as welding, high-strength bolt connection, etc. to ensure that the nodes have sufficient strength and rigidity. When welding nodes, the welding quality should be ensured to avoid welding defects such as pores, slag inclusions, cracks, etc. High-strength bolt connections should be tightened according to the specified torque to ensure the tightness and reliability of the connection. In addition, the design of strengthening nodes can be adopted, such as increasing the thickness of the node plate, setting stiffening ribs, etc., to improve the bearing capacity and deformation capacity of the node.

During the construction process, operations should be carried out strictly in accordance with the design requirements and construction specifications. Ensure the manufacturing accuracy and installation quality of the steel truss to avoid installation deviations and errors. For example, the length, angle and position of the steel truss rods must meet the design requirements, and strict measurements and corrections must be carried out during the installation process. At the same time, attention should be paid to construction safety to avoid damage to the steel truss during construction, which will affect its wind and earthquake resistance.